What is sintered stone made of?

Nov 08, 2023

Sintered stone is made through a process that involves combining natural minerals and then subjecting them to high heat and pressure. The result is a high-performance material that exhibits qualities such as resistance to scratches, stains, heat, and UV light. Sintered stone is known for its versatility, making it suitable for a wide range of applications, including countertops, flooring, wall cladding, and more. The exact composition may vary among manufacturers, but the typical components of sintered stone include:

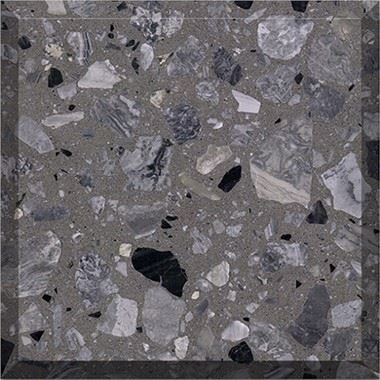

- Natural Minerals: These can include quartz, feldspar, silica, and other minerals sourced from nature. The specific minerals used contribute to the stone's hardness, durability, and aesthetic characteristics.

- Pigments: Various pigments may be added to achieve the desired color and pattern of the final sintered stone product. This allows for a wide range of design possibilities.

- Binders: Some formulations may include binders or additives to enhance the material's cohesive properties during the sintering process. These binders contribute to the strength and resilience of the finished product.

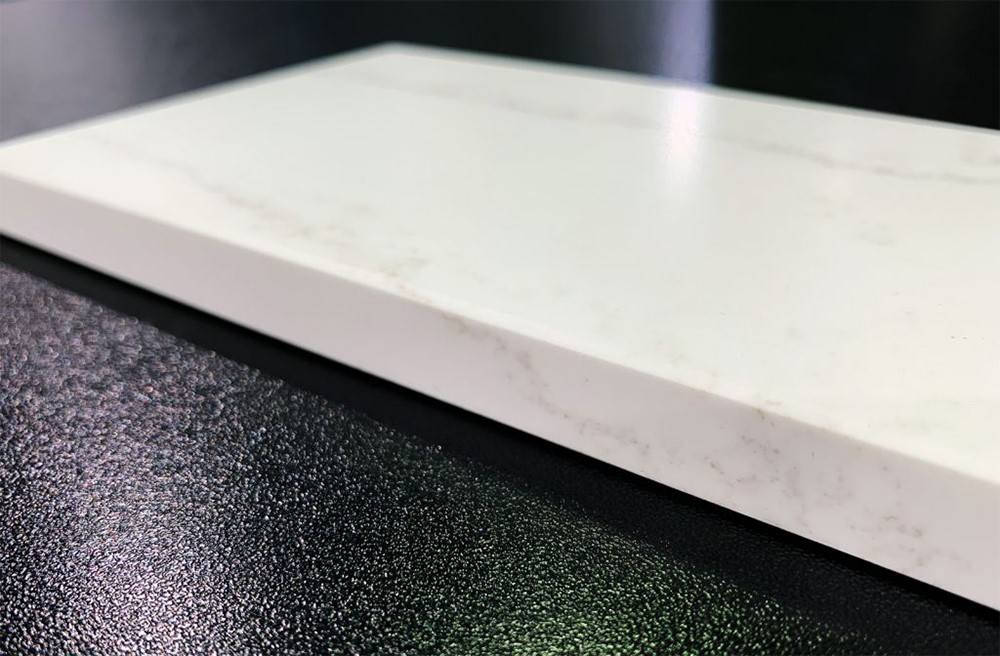

- High Heat and Pressure: The key step in sintered stone production involves subjecting the mixture of natural minerals, pigments, and binders to extremely high temperatures and pressure. This process, known as sintering, causes the particles to fuse together, creating a dense and durable material.

- Advanced Technology: Manufacturers use cutting-edge technology to control the sintering process, ensuring uniformity and consistency in the final product. This technology allows for the creation of large slabs with various thicknesses.

SRS employs state-of-the-art technology and cutting-edge equipment in the production of sintered stone. This includes advanced machinery for mixing raw materials, compacting, curing, and polishing. The use of modern technology ensures precision and efficiency throughout the manufacturing process.

With over 15 years of experience, SRS has assembled a team of experienced and skilled workers, craftsmen, and managers. This collective expertise is crucial in ensuring the quality and consistency of the sintered stone produced. From material selection to the final fabrication, the team's proficiency contributes to the superior quality of the end product.

SRS prioritizes quality control at every stage of production. From the selection of raw materials to the final inspection of finished products, rigorous quality control measures are in place. This commitment to quality ensures that each sintered stone slab meets high standards for durability, aesthetics, and performance. Customers can trust in the reliability and longevity of SRS sintered stone products.